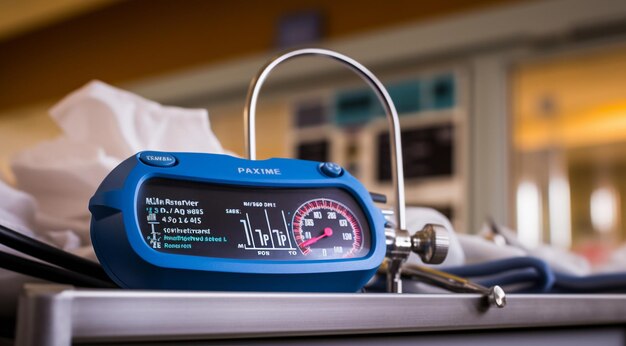

In modern technology, precision and control are key. Vacuum gauges, or vacumetros, are vital in many industries and sciences. These devices measure and maintain vacuum levels. They ensure good conditions for processes. These processes range from making semiconductors to simulating space and sterilizing medical devices.

This article delves into the basics, types, uses, challenges, innovations, and future trends of vacumetrs. It highlights their vital role in shaping technology.

What are Vacumetros?

A vacuum is devoid of matter and is crucial in many technical processes. It can control chemical reactions, heat transfer, and particle movement. Vacumetros are instruments designed to measure and monitor these vacuum levels.

Precise vacuum control is crucial for keeping purity, stopping contamination, and ensuring process reliability. Understanding vacumetrs shows their key role in modern technology. They are important in both theory and use.

Basic Principles of Vacuum Measurement

Measuring a vacuum means knowing its units and scales. Common units are Torr (mmHg), Pascal (Pa), and micron (µm). They show varying pressures in a vacuum.

Vacuum measurement is crucial for industrial processes. It affects their productivity rate. For example, in semiconductor fabrication, it ensures even coatings and high quality.

Types of Vacumetros

Vacuum gauges come in various types. Each range, accuracy, and operating principles suit specific applications.

- Mechanical Gauges

These vacumetros measure vacuum levels using Bourdon tubes or diaphragms. They are reliable and robust, perfect for simple tasks with moderate accuracy needs.

- Ionization Gauges

Measure vacuum levels by ionizing gas molecules within the vacuum. Detect ion currents to find pressure. They are very sensitive and are good for ultra-high vacuum. Researchers and semiconductor experts use them.

- Cold Cathode Gauges

These devices operate by emitting electrons from a cathode. The process depends on the vacuum’s gas pressure. They are both sensitive and durable. Thus, they are excellent for use in industrial and research settings.

- Capacitance Manometers

Vacuum levels are measured by changes in capacitance. This happens when a diaphragm or membrane moves under a vacuum. They are very accurate. They are common in semiconductors and high-precision vacuum systems.

You must understand the differences and uses of these vacuum gauges. This is key for choosing the right tool to measure and control vacuum levels.

Applications of Vacumetros in Various Industries

Vacumetros are widely used in many industries. They have a critical role. They ensure the best conditions and product quality.

- Semiconductor Industry

In the semiconductor industry, vacumetros are crucial. They maintain precise vacuum levels for manufacturing. Vacuum is vital during deposition. It coats silicon wafers with thin materials for semiconductors. Vacumetrs ensure uniformity and quality. They monitor and control the vacuum in chambers. This prevents contamination and safeguards electronic devices.

Also, vacumetrs are crucial in the etching process. They need precise vacuum levels to remove material layers accurately. This helps make advanced microchips and electronic parts.

- Aerospace Industry

In the aerospace industry, vacumetros are used to test space conditions. They are placed in vacuum chambers to replicate the low pressure experienced in space. This setup helps engineers check spacecraft parts and materials. Their goal is to ensure reliability and safety in space.

Vacumetrs are essential for maintaining the right vacuum levels in aerospace simulations. They provide accurate measurements. This is crucial for designing, testing, and approving aerospace systems. These devices play a key role. They are essential for advancing aerospace technology and exploration.

- Medicine and Pharmaceutical Industries

In these fields, vacumetrs help in two main processes. These are vacuum packaging and sterilizing medical items and drugs. Vacuum sealing eliminates air and moisture from products. This preservation method ensures sterility and prolongs their shelf life.

Vacumetros control vacuum levels in packaging and sterilization. In packaging, they maintain product quality and safety. In sterilization, they ensure vacuum cycles work. These cycles remove air from chambers before adding sterilizing agents. This step is crucial for safety and meeting regulatory standards in healthcare.

- Research and Development

Vacumetrs are vital in research and development. They create controlled vacuum environments. These are crucial for studying physical and chemical phenomena. Scientists use them in vacuum chambers. The chambers simulate outer space or specific vacuum levels. This is important in fields like materials science, physics, chemistry, and engineering.

Vacuum gauges help researchers recreate and study conditions. These conditions are hard to achieve at normal air pressures. These tools are crucial in particle accelerators and for material testing. They boost research and development in various scientific fields, leading to innovation.

In each industry, vacumetros help with efficiency, reliability, and quality. They enable precise measurement and control of vacuum conditions. These conditions are critical to their processes and applications.

Challenges in Vacuum Measurement

Despite their critical role, vacuum measurement poses several challenges, including:

Accuracy and Calibration

Achieving and keeping accurate vacuum measurements is hard. This is especially true across varying pressure ranges.

Contamination and Degassing

Minimizing contamination is challenging. It comes from gases left behind and from outgassing in vacuum systems.

Leak Detection

It’s also hard to find and seal leaks in these devices. This is necessary to keep the desired vacuum levels.

Innovations in Vacuum Measurement

Recent innovations aim to address the above challenges. They also aim to enhance their performance and reliability. Advances include:

Digital Vacuum Gauges

Digital technology is integrated for real-time monitoring and data logging. It logs vacuum levels, improving accuracy and access to measurements.

Miniaturization and Integration

Development of compact and integrated vacuum gauges suitable for portable and space-constrained applications.

IoT and Automation

Vacumetros will integrate with Internet of Things (IoT) platforms. This will enable remote monitoring, predictive maintenance, and automated control of vacuum systems.

The innovations show ongoing efforts to improve vacuum measurement. They will enhance their use in many industries and sciences.

Future Trends and Outlook

Vacumetros’ future is set for more advancements. These will come from tech innovation and changing industrial needs.

Advanced Materials and Nanotechnology

Vacuum levels in nanoscale and advanced materials research will likely have more demand. It will boost demand for vacumetros that can measure and control them.

Energy Efficiency

Energy-efficient vacuum systems and gauges will be developed. They will minimize power use and environmental harm.

Integration with Industry 4.0

Vacumetros are now in smart factories and digital manufacturing. They match automated production. Their technology is advancing. It boosts industrial productivity, research, and innovation.

Conclusion

Vacuum meters are crucial in modern technology. They precisely measure and control vacuum levels. This is essential for industrial and scientific processes. They are used in semiconductor manufacturing, aerospace testing, and medical sterilization. They ensure optimal conditions and product quality.

Technological advancements and industrial demands are evolving. Innovation in vacumetros is ongoing. It will keep improving its performance, reliability, and integration in various industries.